MLC

Monument Lettering Center

A History of Monument Lettering and Design

Forward

Much writing has been done on the subject of the pre-industrialized “colonial” gravestones of North America between the seventeenth and eighteenth centuries. The craftsmen of this period predominately used slate or sandstone to create beautiful yet mostly rudimentary memorials. The lettering was typically of a modern “printer’s roman” style which varied from carver to carver, containing ligatures and unique anomalies often used to correct mistakes due to a lack of laying out an inscription prior to carving. Some writing has been done specifically on the lettering of this period, but very little. Even less information can be found on the engraved letterforms of the memorials of the late 19th and early 20th centuries. The Monument Lettering Center picks up its research here, after the industrial revolution, and as a more collective lettering and design ideology begins to emerge in the burgeoning monument industry.

1850s

Around the mid nineteenth century, on the heals of the industrial revolution, monuments were still largely created by hand; typically of marble, a soft stone beautifully suited for hand carving. Highly specialized letter carvers are employed to engrave inscriptions, using varied alphabets and lettering styles, mostly following the lead of popular print/advertising design and lettering styles outside of the monument industry.

1860s

1865: Civil War Headstone Project Begins

1870: Sandblasting is Invented

Benjamin C. Tilghman invents and patents the sandblasting process. Throughout the 1870s Tilghman would continue to improve upon his design and apply for new patents. At this point in time sandblasting is mainly used for sharpening and cleaning metals, and etching glass.

1870s

1873: Civil War Veteran Headstones

1875: Sandblasting Used for Memorial Engraving

1880s: The Popularity of Granite Rises

1890s

New methods are being employed to increase production speed and quality of gravestone manufacturing, and the occupation of memorial draftsman is created.

Mid 1890s*: Mr. Jack's Old English Capitals Printed

William Jack becomes one of the first memorial draftsmen and produces a book of full sized old english capitals intended for reproduction by tracing, one of the first books of its kind.

Early 1900s: Increased Standardization of Monument Lettering Styles

Efforts to speed up the memorial making process continue. Standardized lettering styles specific to the monument industry begin to be more thoroughly documented and distributed through articles in trade publications, the creation of lettering plates, and the printing of lettering books. These advances begin giving less specialized workers the ability to complete the lettering on a memorial.

1912-1915: F.A. Church's Practical Lettering Method

F.A. Church begins his Practical Lettering for Memorials column in the American Stone Trade magazine, with the intent of educating the industry on a mechanical process to allow less skilled draftsmen to lay out lettering without freehand drawing. Church will go on to have a book printed under the same name.

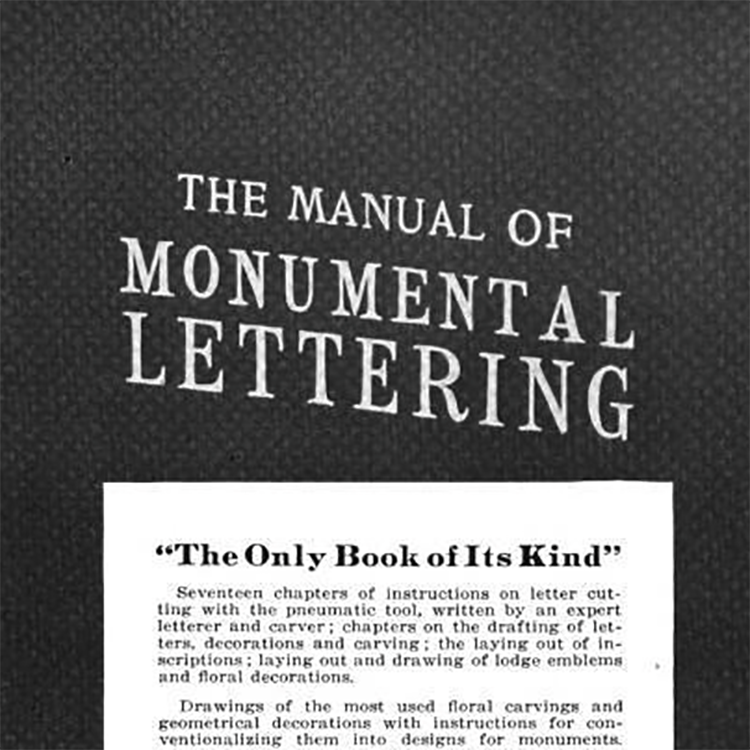

1921: The Manual of Monumental Lettering Printed

The Monumental News Magazine publishes the Manual of Monumental Lettering, the first book of its kind.

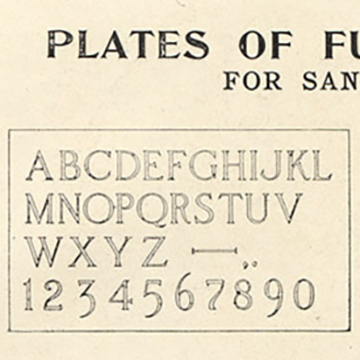

1921: Robert Knox Lettering Plates

Robert B. Knox of the Jones Bros. Company creates and markets lettering plates for quickly laying out lettering on stone. He takes out an advertisement for his plates in the back of the Manual of Monumental Lettering book.

1923: Lettering in Marble Printed

The Vermont Marble Co. produces and distributes its lettering book to the monument industry. The book contains examples of the established memorial lettering styles.

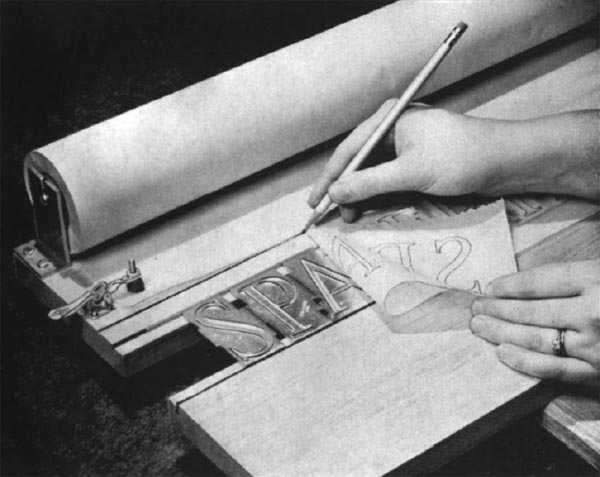

1925: The Spacerite System

George DiBona and Timothy Jellow patent metal letters for tracing an inscription and the Spacerite Company is born, dramatically reducing the time it takes to lay out an inscription on memorials. The system removes the need for a skilled draftsmen to draw lettering by hand.

Late 1920s and 1930s: Continued Diversity in Monument Alphabets

Though the Spacerite system is gaining ground in the monument industry, many memorialists continue to draw their own lettering by hand, and others begin to create lettering plates and blueprints of their own alphabets to be used by the industry for laying out letters and inscriptions. Sandblasting is quickly gaining popularity and begins to overtake carving inscriptions by hand.

Late 1920s*: Matthew Lindsly Blueprints

Draftsmen Matthew Lindsly produces a large series of design and lettering blueprint templates and sells them to the monument industry.

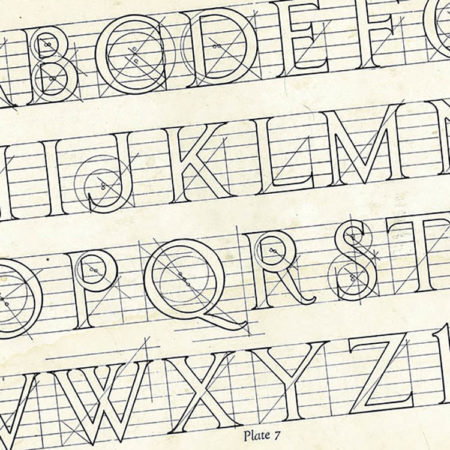

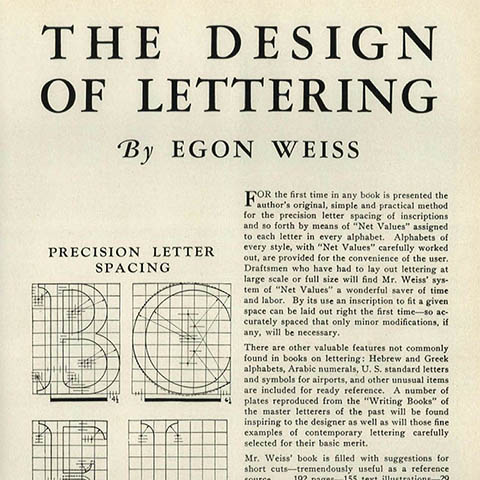

1932: Egon Weiss' Lettering Book Printed

Pencil Points Magazine publishes a lettering book by architect Egon Weiss which is based on his articles published in 1928. A crossover publication covering both print and memorial lettering, the book contained a new system for spacing inscriptions, and would go on to be hugely influential in the industry.

1937: Floyd A. Holes Company Lettering Plates

The Floyd A. Holes Company (later “Holes & McClellan”) begins producing lettering plates for the industry based on the work of Egon Weiss and his letter spacing system. The plates are first introduced at the 1937 Memorial Craftsmen of America national convention.

1940s

By 1940 sandblasting has completely overtaken hand carving as the method used for engraving memorials, the Spacerite letter system has been widely adopted by the industry, and the first stencil die-cutting letters are invented and produced.

1940: Presto Cut Letters

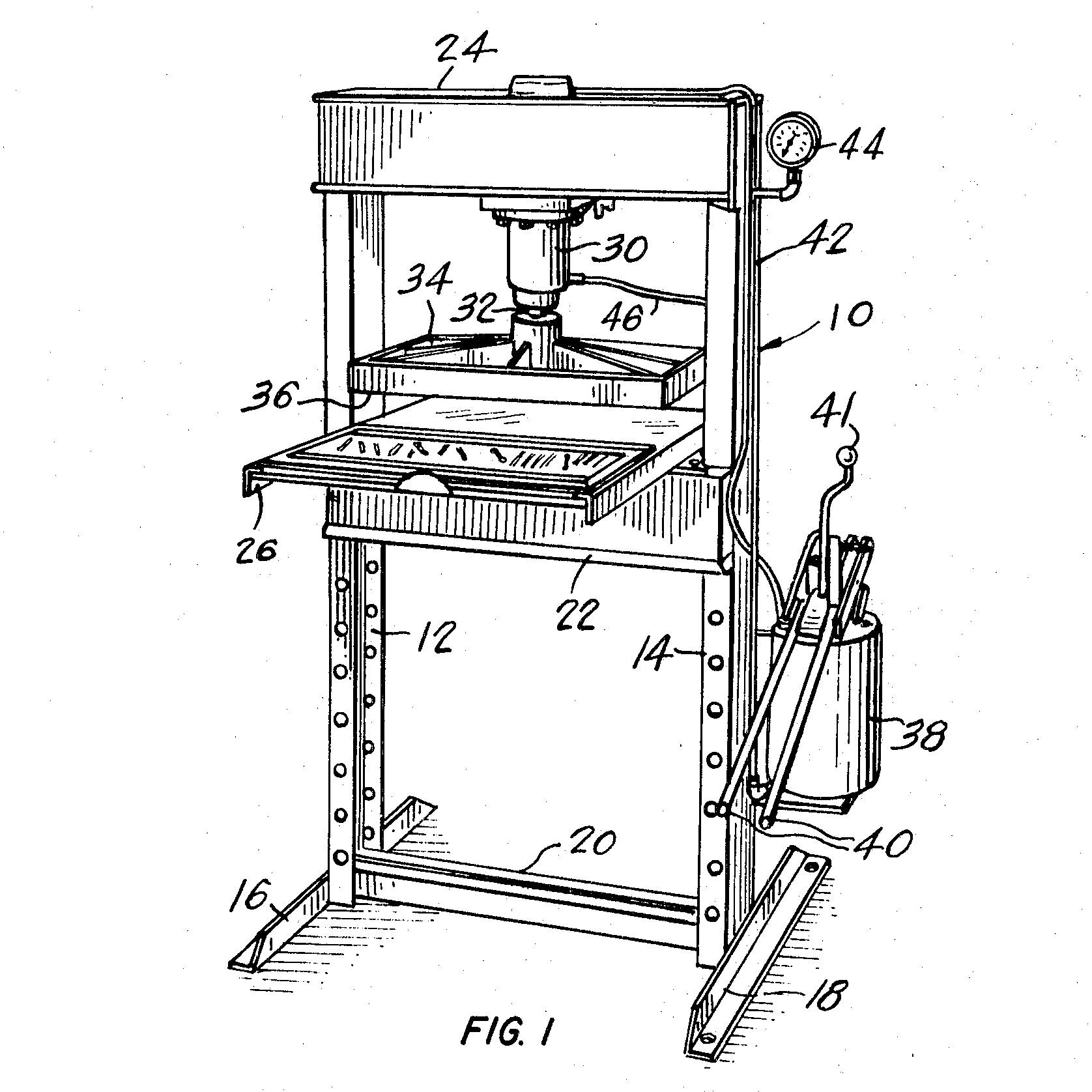

Emile C. Franzmann invents and patents the industries first stencil die-cutting letters. The Presto Cut system eliminates the need for hand cutting stencil, but is still somewhat tedious and sees limited success.

1943: Sand-Craft Service

Sand-Craft Service of Oshkosh, WI begins producing a series of design portfolio manuals for sandblast engraving. The series continued for some 20 years. The blueprint or full color design books include full-size designs, design elements, emblems, and alphabet examples.

1950s and early 1960s

Though the Spacerite system still reigns supreme, there is some pushback against the predictability and monotony of the lettering. Many manufacturers begin creating their own alphabets for reproduction, and modifying the Spacerite letters during the stencil-cutting process, creating sans-serif and other variations of the alphabets. Though it has become increasingly rare to see hand drawn lettering on headstones, there is a slight resurgence during this period.

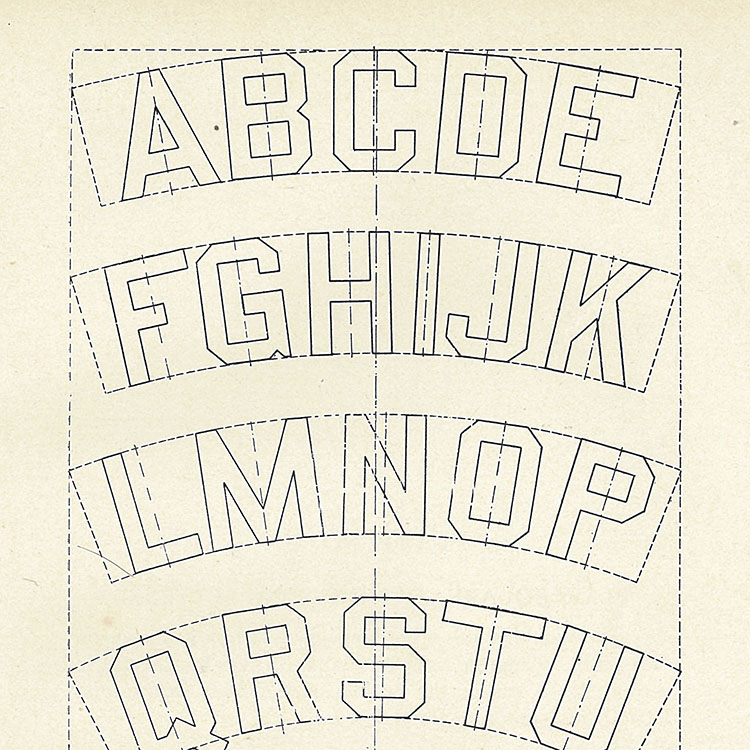

1968: Plastic Cutting Dies and the Stencil Press

The stencil press is invented and patented simultaneously by two companies, and plastic stencil cutting alphabets and designs are created. The time taken to lay out and cut a design and inscription in stencil is drastically reduced. Two Companies immediately kick off the stencil press revolution: SKS Limited and Gaspari.

Gaspari and PALL

In 1968 Anthony M. Gaspari applies for patents for both stencil cutting letters and a stencil press machine, and immediately teams up with PALL (Canada) Limited. PALL’s Stencil Cutting Machine Division begins distributing Gaspari stencil cutting dies and equipment.

SKS Limited

SKS is created by Edmund Sandborn and Alfred Azzopardi in 1968. The duo applies for patents for both stencil cutting alphabets and a stencil press machine—at the same time as PALL and Gaspari are applying for their alphabet and press machine patents.

1970s

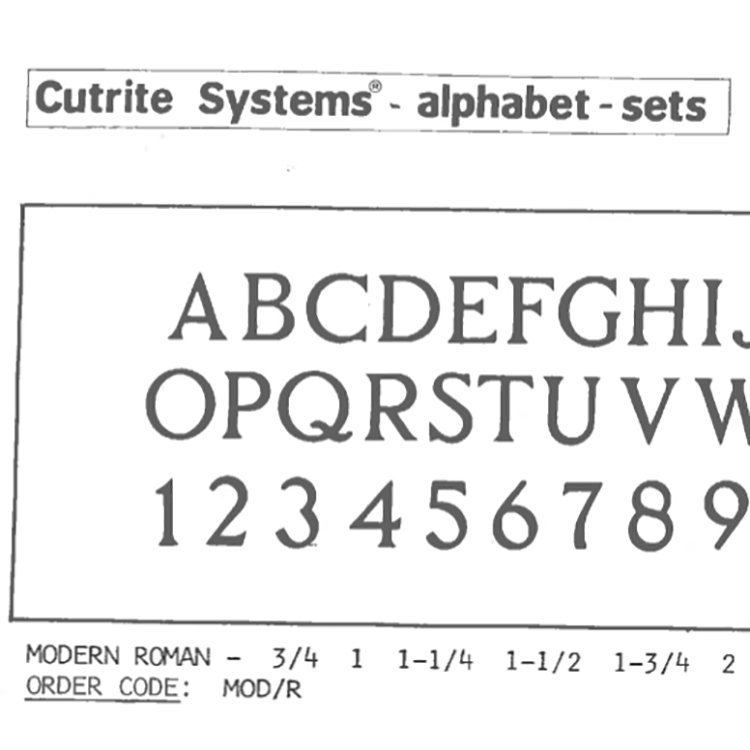

Stencil cutting dies continue to saturate the industry as more and more monument manufacturers begin using the stencil press for cutting memorial designs in stencil. New stencil press design companies are created, giving birth to many versions of the classic memorial alphabets, as well as never before seen lettering styles.

Early 1970s*: SKS Obtains PALL Cutting Dies

The SKS Ltd Company purchases the PALL line of stencil cutting dies.

Early 1970s*: Allied Industrial Sales Corporation

Around the same time as the SKS purchase of PALL, with the help of his father Anthony, John Gaspari teams up with Imre Adler to produce stencil press letters and designs under the name Allied Industrial Sales Corp.

1975: SKS Limited becomes ScotchKut Systems

The 3M Company purchases SKS Limited and produces the stencil cutting dies under the new name: ScotchKut Systems.

1976: PMD & Cutrite Systems

The Allied Industrial Sales Corporation cutting die operation changes hands. PMD International is born, and the alphabets are marketed under the name Cutrite Systems.

1980s

The monument industry sees its first use of CAD (computer aided design) systems and mechanical cutting plotters.

1986: Monu-Cad memorial design software is created

In 1986, Monumental Computer Applications, Inc. begins marketing its monument industry specific computer software, Monu-Cad. The system includes CAD software and a stencil cutting system to replace the need for hours of manual labor.

1987: Cochran's Monument Design Software

In 1987 Cochran’s Monuments begins marketing a CAD system for creating designs and cutting sandblast stencil under the name Cochran’s Quick-Cut Systems.

1990s

Computer aided design (CAD) software and stencil-cutting machines begin taking over. The trend towards personalized and “pictorial” memorials that began in the late 1980s continues to grow.

1990*: The Spacerite Company Closes

The Spacerite Company was able to survive through the stencil press era, but around 1990 the company closes its doors and Granite City Tool of Vermont purchases the remaining production equipment. New Spacerite alphabets can still be purchased through GCT.

2000s

Though there are still some who prefer the old methods, the computer era of monument design is well underway. The flexibility and speed of using computer systems for designing memorials further heightens the growing shift towards personalized memorial designs.

2003: ScotchKut Systems Discontinued

The demand for plastic cutting dies dwindles. The 3M Company makes the decision to discontinue ScotchKut Systems, selling the remaining stock and molds to Granite City Tool of Vermont, but keeps the name trademark. Granite City Tool continues to produce the cutting dies for the industry under the name SKS.

2008: MemorialDESIGNER Software Released

Beginning at a single monument shop in the mid 1990s, the MemorialDESIGNER suite of tools for CorelDRAW is first released to other monument companies. With an emphasis on creating color renderings, as well as speeding up and simplifying the design process, the software marks a giant leap forward in keeping the industry in step with modern computer graphics. It is the only memorial design software which utilizes the power of drawing with Wacom tablets, and fully supports OpenType fonts and features–a perfect match for MLC fonts.

www.monumentletteringcenter.com © 2016-2024